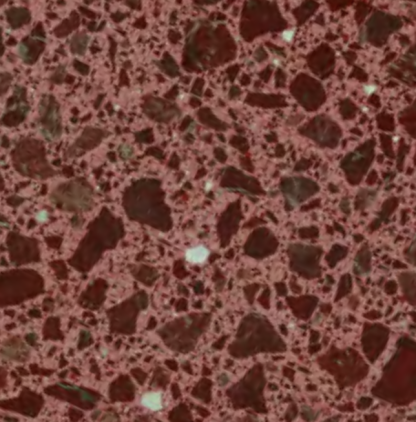

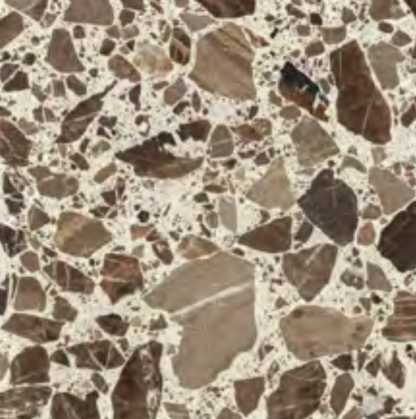

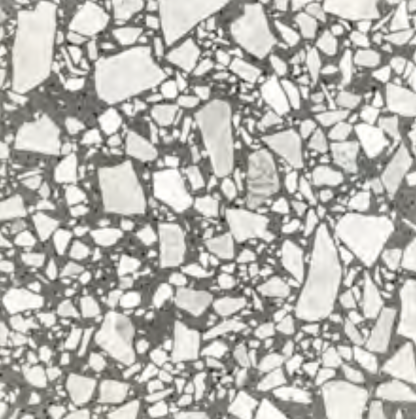

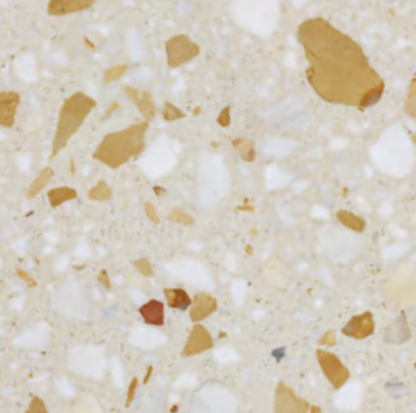

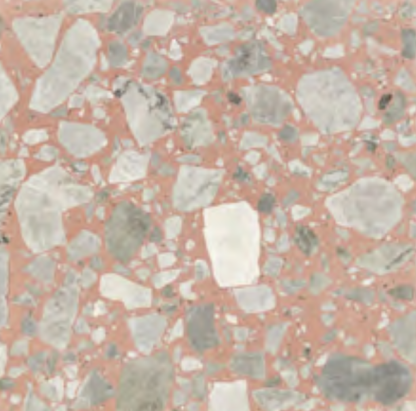

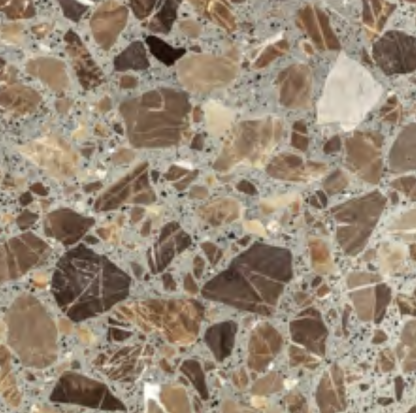

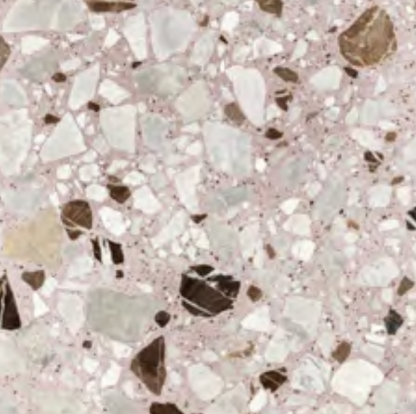

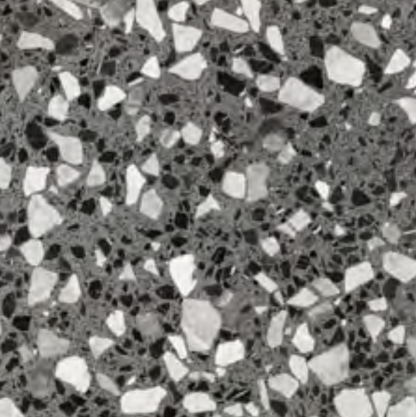

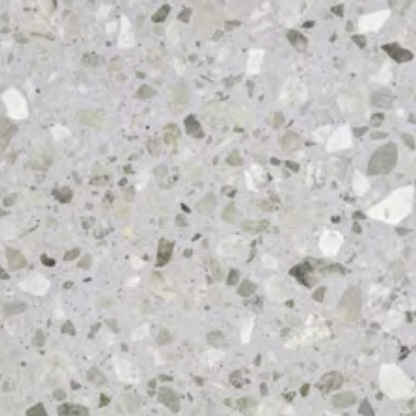

What is terazzo?

Terrazzo is a composite material, typically consisting of chips of marble, quartz, granite, glass, or other suitable material, poured with a cementitious binder. The specific stones used in terrazzo can vary depending on the desired aesthetic and performance characteristics. Traditionally, marble chips were commonly used, but nowadays, terrazzo can incorporate a wide range of stone aggregates, including those mentioned earlier. The choice of stone can affect the final appearance, texture, and durability of the terrazzo surface.

How is terazzo formed?

Terrazzo is formed through a process that involves embedding chips of marble, quartz, granite, glass, or other suitable aggregates into a binder material, such as cementitious or epoxy resin. The process typically involves several steps:

Mix Preparation: The terrazzo mix is prepared by combining the selected aggregates with the chosen binder material. The proportions of aggregates to binder are carefully measured to achieve the desired appearance and performance characteristics.

Surface Preparation: The surface where the terrazzo will be installed is prepared by cleaning, leveling, and priming as necessary to ensure proper adhesion of the terrazzo mix.

Pouring: The prepared terrazzo mix is poured onto the prepared surface and spread evenly to the desired thickness. Dividers or strips may be used to create different sections or patterns if desired.

Compaction: Once the terrazzo mix is poured, it is compacted to remove air pockets and ensure a dense, uniform surface. This may involve using rollers or trowels to smooth and compress the mixture.

Curing: The terrazzo mix is allowed to cure and harden over a specified period of time, typically several days, depending on the type of binder used and environmental conditions.

Grinding: After the terrazzo has cured, the surface is ground down to expose the embedded aggregate chips and achieve a smooth, level finish. This is typically done using grinding equipment with progressively finer abrasives to achieve the desired level of polish.

Polishing: Once grinding is complete, the terrazzo surface may be polished to further enhance its appearance and durability. Polishing compounds and equipment such as floor polishers with diamond abrasive pads are used to achieve the desired level of shine.

Sealing: Finally, the terrazzo surface may be sealed to protect it from stains, moisture, and wear. Sealants are applied to the surface and allowed to cure, providing an additional layer of protection and enhancing the longevity of the terrazzo.

Overall, the process of forming terrazzo involves a combination of craftsmanship, attention to detail, and specialized equipment to create durable, beautiful surfaces suitable for a wide range of applications.

Where is terazzo used?

Terrazzo is a versatile material that can be used in various architectural and interior design applications. Some common places where terrazzo is used include:

Flooring: One of the most common applications of terrazzo is as a flooring material. It is highly durable, easy to maintain, and can be customized with different aggregate colors and sizes to create unique patterns and designs.

Countertops: Terrazzo countertops are popular in kitchens and bathrooms. They provide a durable and hygienic surface that is resistant to stains and scratches.

Walls and Partitions: Terrazzo can be used to clad walls and partitions, adding texture and visual interest to interior spaces.

Staircases: Terrazzo can be used to cover staircases, providing a durable and slip-resistant surface.

Furniture and Accessories: Terrazzo can also be used to make furniture, such as tabletops and benches, as well as decorative accessories like vases and trays.

Public Spaces: Terrazzo is commonly found in public buildings such as airports, schools, and museums due to its durability and ease of maintenance.

Outdoor Spaces: Terrazzo can also be used in outdoor applications such as patios, walkways, and pool decks, especially when installed with appropriate sealants to protect against weathering.

Overall, terrazzo's versatility, durability, and aesthetic appeal make it a popular choice for a wide range of applications in both residential and commercial settings.

Is terazzo resistant to heat?

The resistance of terrazzo to heat can vary depending on the specific materials used in its composition and the type of binder used to hold the aggregate together. In general, terrazzo made with cementitious binders may not be as heat-resistant as terrazzo made with epoxy binders.

Cement-based terrazzo can withstand moderate heat, but prolonged exposure to high temperatures or direct contact with hot objects can potentially cause damage such as discoloration or cracking. It's important to use trivets or hot pads under hot cookware to protect the surface.

Epoxy terrazzo, on the other hand, tends to have better heat resistance compared to cement-based terrazzo. Epoxy binders are more resistant to heat and can withstand higher temperatures without significant damage. However, it's still advisable to use caution and avoid placing extremely hot objects directly on the surface for extended periods.

In any case, to ensure the longevity and performance of terrazzo surfaces, it's best to follow manufacturer recommendations for maintenance and care, including avoiding exposure to excessive heat.

Does terazzo crack?

Terrazzo is a durable material, but like any flooring or surface material, it can potentially crack under certain conditions. The likelihood of cracking depends on various factors including the quality of installation, substrate preparation, environmental conditions, and the type of terrazzo (cementitious or epoxy-based).

Here are some factors that can contribute to terrazzo cracking:

Substrate Issues: If the substrate (the surface onto which the terrazzo is applied) is not properly prepared or if there are structural issues with the building, it can lead to cracking in the terrazzo.

Settlement: Changes in the building's foundation or settling of the substrate over time can cause stress on the terrazzo surface, leading to cracking.

Temperature Changes: Extreme temperature fluctuations can cause materials to expand and contract, which may result in cracking, especially if the terrazzo is not properly designed to accommodate these movements.

Impact: Heavy impacts or sharp blows can cause localized damage to the terrazzo, resulting in cracks.

Poor Installation: Incorrect installation techniques or inadequate curing of the terrazzo can also contribute to cracking issues.

While terrazzo is generally resistant to cracking when installed properly, it's essential to choose experienced professionals for installation and to follow best practices for maintenance and care to minimize the risk of cracking over time. Additionally, selecting the appropriate type of terrazzo and considering the specific conditions of the installation site can help mitigate potential cracking problems.

Does terazzo stain?

Terrazzo, like any porous surface, can be susceptible to staining if spills are not promptly cleaned up or if the surface is not properly sealed. The porosity of the terrazzo and the type of binder used in its composition can influence its stain resistance.

Here's how staining can occur and how it can be prevented:

Porosity: Terrazzo surfaces can be porous, especially if they are made with cementitious binders. This porosity can allow liquids to penetrate the surface, leading to staining. Epoxy-based terrazzo tends to be less porous and therefore more resistant to staining.

Sealing: Properly sealing the terrazzo surface with an appropriate sealant is essential for stain resistance. Sealants help create a protective barrier that prevents liquids from penetrating the surface and makes it easier to clean spills.

Prompt Cleaning: Spills should be cleaned up promptly to prevent them from staining the terrazzo. Using a mild detergent and water, along with a soft cloth or mop, can help remove spills before they have a chance to set and stain the surface.

Avoid Harsh Chemicals: Harsh cleaning chemicals or acidic substances can potentially damage the terrazzo surface and make it more susceptible to staining. It's best to use mild cleaning agents and avoid abrasive cleaners that could scratch or wear down the sealant.

Regular Maintenance: Periodic maintenance such as resealing the terrazzo surface as needed can help maintain its stain resistance over time.

Overall, while terrazzo can stain if not properly cared for, regular maintenance and proper sealing can help preserve its appearance and minimize staining issues.

Does terazzo scratch?

Terrazzo is generally a durable material that is resistant to scratching under normal use. However, like any surface, it can be scratched under certain conditions, especially if sharp or abrasive objects are dragged across it with force.

Here are some factors that can contribute to scratching of terrazzo:

Abrasive Materials: Dragging heavy or sharp objects across the surface of terrazzo can cause scratching, especially if the objects have rough or abrasive surfaces.

Improper Maintenance: Using abrasive cleaning tools or harsh chemicals on terrazzo surfaces can wear down the protective sealant layer over time, making the surface more susceptible to scratching.

High Traffic Areas: In high-traffic areas where there is constant foot traffic, particularly with shoes that have hard or abrasive soles, the surface of terrazzo may gradually develop scratches over time.

Grit and Dirt: Dirt, sand, or grit that is tracked onto the terrazzo surface can act like sandpaper when walked on, potentially causing scratching if not promptly removed.

While terrazzo is resilient and can withstand a considerable amount of wear and tear, it's essential to take precautions to minimize the risk of scratching. Regular cleaning with a soft mop or cloth, using furniture pads under heavy objects, and avoiding dragging sharp or abrasive items across the surface can help preserve the appearance of terrazzo and minimize scratching. Additionally, maintaining the protective sealant layer through periodic resealing can help enhance scratch resistance.

Do terazzo countertops increase home value?

Terrazzo countertops can potentially increase the value of a home, but the extent of their impact on home value depends on various factors including the quality of the installation, the overall design aesthetic, and the preferences of potential buyers.

Here are some factors to consider regarding the impact of terrazzo countertops on home value:

Aesthetic Appeal: Terrazzo countertops can add a unique and stylish aesthetic to a kitchen or bathroom, which may appeal to buyers seeking modern or upscale features. If the terrazzo is well-designed and complements the overall design of the space, it can enhance the perceived value of the home.

Durability and Longevity: Terrazzo is a durable material that can withstand daily wear and tear, making it an attractive option for countertops. Homebuyers may perceive terrazzo countertops as a long-term investment, which can positively influence their perception of the home's overall value.

Customization Options: Terrazzo countertops offer a wide range of customization options in terms of color, aggregate selection, and design patterns. Customized features that reflect the homeowner's unique style preferences can enhance the appeal and value of the home.

Market Demand: The demand for terrazzo countertops may vary depending on regional preferences and trends in the housing market. In areas where terrazzo is popular or considered desirable,

Should terazzo be sealed?

Yes, terrazzo should typically be sealed to protect the surface and enhance its durability and resistance to stains, scratches, and other forms of damage. Sealing terrazzo helps to create a protective barrier that prevents liquids, oils, and other substances from penetrating the surface and causing stains. It also makes the surface easier to clean and maintain.

Sealing terrazzo is especially important because it is a porous material, particularly if it is made with a cementitious binder. Epoxy terrazzo, while less porous than cement-based terrazzo, can also benefit from sealing to further protect the surface.

The frequency of sealing depends on various factors including the type of terrazzo, the level of use and traffic it receives, and the specific sealant used. In general, terrazzo should be sealed upon installation and periodically resealed as needed to maintain optimal protection and performance. Your terrazzo installer or manufacturer can provide recommendations on the appropriate sealant and sealing schedule for your specific terrazzo surface.

Can terazzo be used outside?

Yes, terrazzo can be used outside in certain applications, but it requires proper installation and maintenance to ensure durability and longevity, especially in outdoor environments where it is exposed to the elements.

Here are some considerations for using terrazzo outside:

Climate and Weather Conditions: Terrazzo can be susceptible to damage from exposure to extreme temperatures, moisture, UV radiation, and freeze-thaw cycles. In regions with harsh climates, it's essential to use terrazzo products specifically designed for outdoor use and to follow proper installation practices to mitigate potential weather-related damage.

Substrate Preparation: Proper preparation of the substrate is crucial for outdoor terrazzo installations to ensure stability and prevent issues such as cracking or shifting. The substrate should be adequately sloped for drainage and prepared to withstand outdoor conditions.

Sealing and Maintenance: Outdoor terrazzo surfaces should be sealed with a high-quality sealant that is specifically formulated for outdoor use to protect against moisture penetration, staining, and UV damage. Additionally, regular maintenance such as cleaning and resealing may be necessary to preserve the appearance and performance of the terrazzo over time.

Slip Resistance: Slip resistance is an important consideration for outdoor terrazzo installations, especially in areas prone to wet conditions. Textured or non-slip finishes can be applied to the surface to enhance traction and reduce the risk of slips and falls.

Design and Aesthetics: When using terrazzo outdoors, it's important to consider factors such as color stability and resistance to fading in direct sunlight. Choosing aggregates and binders that are suitable for outdoor use can help maintain the desired aesthetic appearance over time.

Overall, while terrazzo can be used outside in certain applications such as patios, walkways, and pool decks, it's important to consult with a qualified installer or manufacturer to ensure that the terrazzo product selected is suitable for outdoor use and that proper installation and maintenance practices are followed to maximize its durability and performance.

Terrazzo is a composite material, typically consisting of chips of marble, quartz, granite, glass, or other suitable material, poured with a cementitious binder. The specific stones used in terrazzo can vary depending on the desired aesthetic and performance characteristics. Traditionally, marble chips were commonly used, but nowadays, terrazzo can incorporate a wide range of stone aggregates, including those mentioned earlier. The choice of stone can affect the final appearance, texture, and durability of the terrazzo surface.

The fabrication process for terrazzo typically involves several steps:

1 Design and Planning: This step involves conceptualizing the design, choosing the types and colors of aggregates (stones and/or glass), and determining the layout.

2 Surface Preparation: The surface where the terrazzo will be installed needs to be properly prepared. This may involve cleaning, leveling, and priming the substrate.

3 Mix Preparation: The terrazzo mix consists of the chosen aggregates (stone chips, glass, etc.) and a binder material, often cementitious or epoxy-based. The mix proportions are carefully calculated to achieve the desired look and performance.

4 Pouring: The prepared terrazzo mix is poured onto the prepared surface and spread evenly to the desired thickness. During this step, dividers or strips may be used to create different sections or patterns if desired.

5 Grinding: Once the terrazzo mix has cured sufficiently, typically after a day or two, the surface is ground down to expose the aggregate chips and achieve a smooth, level finish. This may involve multiple passes with progressively finer abrasives.

6 Polishing: After grinding, the terrazzo surface is polished to enhance its appearance and durability. This may involve using polishing compounds and equipment such as floor polishers with diamond abrasive pads.

7 Sealing and Protection: Finally, the terrazzo surface is sealed to protect it from stains and moisture. Different sealers may be used depending on whether the terrazzo is installed indoors or outdoors.

Each of these steps requires skill and attention to detail to ensure a high-quality finished product. Additionally, specialized equipment and tools may be necessary for certain stages of the fabrication process.